Industrial-Grade Networking for Egypt’s First Automated Tile Factory, Ceramica Platino

Introduction

As Egypt’s first fully automated ceramic tile manufacturer, Ceramica Platino Group is doing more than producing tiles, it’s setting a new benchmark for industrial innovation. With a strong track record in porcelain and ceramic production, the company has built a reputation as a regional leader, exporting to markets across the Middle East and Europe

At the heart of Ceramica Platino’s growth is a commitment to smart, sustainable, and precision-driven manufacturing. Powered by robotics, AI, and IoT, its operations demand more than just machinery, they require a network infrastructure that is fast, intelligent, and resilient. As the company expanded automation and introduced AI-driven design, maintenance, and monitoring, its legacy systems began to reach their limits, prompting the need for a next-generation industrial network built to support scale, integration, and uninterrupted performance.

Scaling a Smart Factory in Harsh, Real-World Conditions

With digital operations expanding and new production lines coming online, Ceramica Platino needed a partner who could design and deliver an industrial-grade network, fast, stable, and future-proof.

A Trusted Technical Partner for Factory-Specific Needs

To navigate this complex upgrade, Ceramica Platino needed more than a vendor, they needed a technical partner. This confidence extended from rigorous pre-project testing, reliable implementation, to consistent post-deployment support, ensuring long-term success in their demanding setting.

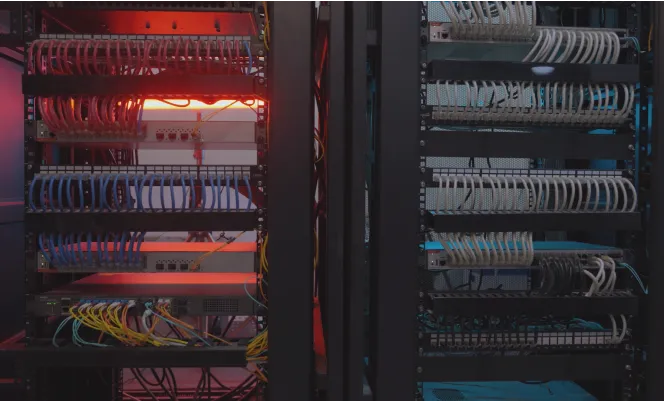

The Imperative for Industrial-Grade Hardware

Existing legacy network equipment has reached end-of-sale. Crucially, it lacked the high-specification hardware required to endure the extreme temperatures, abrasive dust, moisture, and electromagnetic interference inherent in ceramic tile production. This fundamental mismatch led to instability and made it unsustainable for critical future operations.

Zero Downtime Seamless Integration

The network supports not only employees, but also robotic lines, sensors, and OT systems, making any upgrade a delicate task due to the factory’s 24/7 operations. A reliable, future-ready solution was required to integrate seamlessly with existing infrastructure, including legacy IP phones and industrial equipment with older PoE requirements, all while enhancing operations without disrupting the continuous manufacturing flow.

Balancing Performance with Predictable Costs

Ceramica Platino sought a comprehensive network solution that combined high performance with upfront costs suited to an industrial scale. Crucially, they needed to avoid recurring subscription fees and ensure easy, efficient monitoring without adding complexity or burden to their lean IT operations.

A Partnership Delivering Enduring Industrial Connectivity

The journey began with a strategic pilot deployment, carried out in close collaboration with the factory’s engineering team. Industrial-grade switches and access points were introduced in key areas of the facility, where their performance, compatibility, and reliability proved essential. This success laid the groundwork for the next phase, a comprehensive network tailored to demanding industrial use cases, supported by a strong partnership that truly understood the factory’s unique environment.

A Partner to Trust in an Industrial Setting

Engineers maintained close communication with the plant team, conducting on-site assessments and fine-tuning configurations for the factory’s unique operational requirements. This collaborative partnership, from initial pilot testing to seamless implementation and robust post-deployment support, instilled the confidence Ceramica Platino needed in their critical network infrastructure and chosen provider.

Designed for the Factory Floor

The comprehensive solution deployed included a purpose-built industrial network switch series, strategically chosen for its robust, high-specification design. This hardware was specifically engineered to withstand Ceramica Platino’s uniquely challenging environment, where standard enterprise-grade equipment would simply fail, ensuring unwavering reliability across all operations.

Non-Disruptive Seamless Integration & Reliable Upgrade

Field engineers carried out meticulous pre-configuration and a phased deployment, enabling a seamless switch-over with zero downtime, a critical achievement for a facility that operates around the clock. Comprehensive on-site assessments were conducted to optimise the network topology for the factory’s unique conditions. Crucially, the solution provider’s R&D team worked closely with Ceramica Platino to customise software for compatibility with older PoE standards. This ensured continued, seamless operation of existing IP phones and legacy systems, delivering a reliable upgrade without the need for costly replacements.v

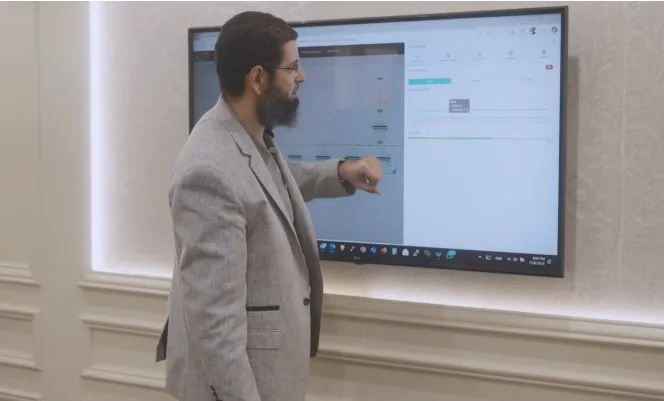

Solution for Cost-Efficient & Simplified Management

Beyond the robust hardware, Ceramica Platino gained a solution designed for long-term value and simplicity. The new infrastructure avoided future subscription costs, ensuring cost-predictability. WIS, the intelligent cloud platform provided real-time visibility, centralised control, and custom SSIDs, significantly enhancing network performance and simplifying overall IT management for their industrial setting.

Ceramica Platino’s decision to modernise its network was driven by a clear objective which is to embed long-term reliability and operational excellence at the heart of its operations, specifically addressing the unique demands of an industrial setting. Anchored by an industrial-grade switch series and supported by a dedicated technical partnership, the solution ensures that every device, from legacy IP phones to modern IoT equipment, remains securely connected and supported, even in Egypt’s most demanding manufacturing environments.

By emphasizing true industrial-grade compatibility, environmental resilience, cost-effectiveness, and truly collaborative problem-solving, the chosen partner demonstrated unwavering trust and full commitment to Ceramica Platino’s success. Today, Ceramica Platino continues its growth with confidence, knowing its network is a robust foundation built for the factory floor, supporting every step forward in its innovative manufacturing journey.